Reduced life expectancy can lead to catastrophic failures as well as increased maintenance and replacement costs...

Offshore cranes work in harsher conditions than their onshore counterparts, exposed to a highly corrosive environment and dynamic loading when conducting lifts from floating vessels.

Some components are more critical to safety than others. Single point failures are the highest level of criticality for any component, resulting in a loss of load or catastrophic failure.

For example, if the engine driving the hydraulic pump failed (with a suspended load), it would not be a single point failure, as the hoist brake/luffing system would hold the load and the operator would be able to make the load safe by other means. However, if the brake or the wire rope failed, it would result in a certain loss of load control.

Identifying single point failures

A Failure Mode, Effects and Critical Analysis (FMECA) study needs to be conducted with representation of operating/maintenance personnel bringing site specific knowledge and a facilitator well versed with FMECA methodology. The study team must have vast experience in crane integrity management and thorough knowledge of industry standards, benchmarks, history of failures and causes. The study generates an invaluable report identifying all the single point failures and defines the maintenance tasks and frequency required to assure integrity of these components.

When loss of integrity for critical components is not readily detectable

For these components, the study team defines the end of useful life, when it is to be changed out regardless of visual condition. Fatigue is one such degradation mechanism that could lead to undetectable failure.

"Are we over maintaining?"

It is common industry practice to strive for continuous improvement and the maintenance budget rarely escapes scrutiny, to ascertain if the maintenance regime is fit for purpose. A FMECA is a valuable tool in assessing if reduced maintenance could result in compromised safety. If change is considered, a FMECA study team should be assembled as before. No one responsible for the safe operation of an offshore crane would cull justifiable critical activity. The FMECA provides robust justification for all stakeholders to make decisions with confidence that safety is not being compromised.

Who does this affect?

Those with an interest in achieving increased component life expectancy and reduced risk of failure and maintenance costs.

How will it help?

Gain an understanding of correct implementation of condition monitoring techniques to provide early warning of failure, reduce the risks of accidents and extend life.

About the Authors

Julio De Melo, Upstream PS has more than 30 years' experience in the oil and gas and marine industries. He leads maintenance engineering and asset integrity programs for onshore and offshore assets.

Luis Rojas, Upstream PS develops interdisciplinary maintenance and integrity projects to deliver asset integrity throughout the lifecycle of the asset.

Daniel Shorten, Lloyd's Register UK promotes best practice and the management of change specifically in relation to asset management and condition based maintenance.

Slew bearing condition monitoring

For the crane to pivot through a full 360 degrees of rotation about a central pedestal, the slew bearing provides the primary operational design requirements and sustains the full load of the crane, its payload and counterbalance. Many slew bearing condition monitoring techniques are available. We have found the analysis of used lubricating grease the most ideal.

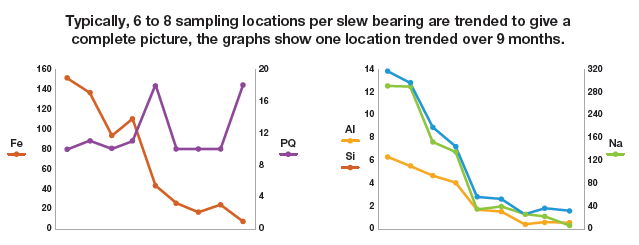

Due to the operational characteristics of slewing bearings, combining erratic load cycling, slow speeds - often much less than 1 rpm – and a lubricant that is not fully mobile, the sampling technique must be carefully structured to ensure good, repeatable and representative results.

Used grease analysis uncovers otherwise hidden failures

Not knowing the condition of a critical component is unsafe practice, however a false sense of security from inadequate condition monitoring is even more dangerous. Used grease analysis, when implemented correctly, will complement existing condition monitoring techniques and provide a comprehensive understanding of the slew bearing condition.

Correct sampling, test methodology and interpretation

In this instance, our authors are primarily interested in the condition of the bearing, and the effect of grease condition. Standard grease analysis tests may be performed to check batch consistency or for development purposes but will not paint the full picture, as distribution of contaminants/wear debris in grease will not, by the nature of slew bearing operation and grease distribution, be homogenous. The grease within the bearing contact voids is effected by external contamination by sea water/salt spray; it collects any material from the bearing as a result of significant overload, fatigue and general wear.

We must employ techniques that ensure test results are representative and clearly indicate bearing deterioration. In addition to correct sampling and analysis techniques, interpretation of results is important, factoring in conditions specific to slew bearing operation.

Since the 1980s Lloyds Register has worked to develop a methodology that meets both the technical and regulatory needs e.g. UK HSE and Norwegian Petroleum Directorate using statutes like the UK LOLER (Lifting Operations and Lifting Operations) SI 2307, which details how the crane should be managed. Lloyds Register carried out a joint research project to understand the relevance of grease testing and the protective regime necessary for safe operations. Upstream PS works with Lloyds Register (London) to implement ‘Used Grease’ condition monitoring on offshore cranes.

Eliminate risk of accidents, enable life extension and extend OPEX

Used grease analysis, when trended, using a consistent approach to greasing and sampling, can provide an early warning on material failure. Remedial action can then be taken to arrest the degradation and extend the life of the slew bearing, reducing and ultimately eliminating the risk of accidents, and delivering financial benefit.

Pedestal structure condition monitoring

The crane structure is designed to transfer forces from loads being lifted to the crane pedestal support. Offshore environmental conditions (winds, waves) induce additional dynamic cyclic forces to be supported. Operational forces can potentially take the crane structure to its operational limits or beyond. Fatigue must also be addressed.

Relying on visual inspection could mean operating close to failure

Visual inspection of structural components is common practice, reporting defects like cracks/corrosion etc., but this would identify a defect well after the event has occurred and the components could be operating close to failure. We also noted that typical visual inspections are reported by exception and not on every structural component. This could lead to missing a component, inconsistent reporting and inability to track condition accurately. This led us to implement a process reporting on all components.

Developing a cost effective and practical - yet robust - approach to inspection

Upstream PS worked with API qualified crane technicians and companies with NDT (Non-Destructive Testing) capability/structural engineering support to develop an approach using a combination of visual and Eddy Current Inspection (ECI). If there was reason to inspect further, it would escalate to Magnetic Particle Inspection (MPI). Ultrasonic Testing (UT) inspections measured wall thickness where required.

With detailed structural drawings (with the weld maps) from the crane manufacturer, the structure was broken into manageable subassemblies. Each structural member and weld was catalogued with a unique identifier. The FMECA identified single point failure structures and frequencies of inspections. A detailed Inspection and Test Plan was developed, forming the basis of checklists and reporting sheets. We addressed all the deficiencies identified and created a robust structural inspection program.

For more information contact info@upstreamps.com

Download the article as a PDF: Condition monitoring for the safe operation and life extension of offshore cranes

© Copyright 2016 Upstream Production Solutions PTY LTD. All Rights Reserved